Which logistics strategy is better?

Comparison of two scenarios – AMR robots with different speeds

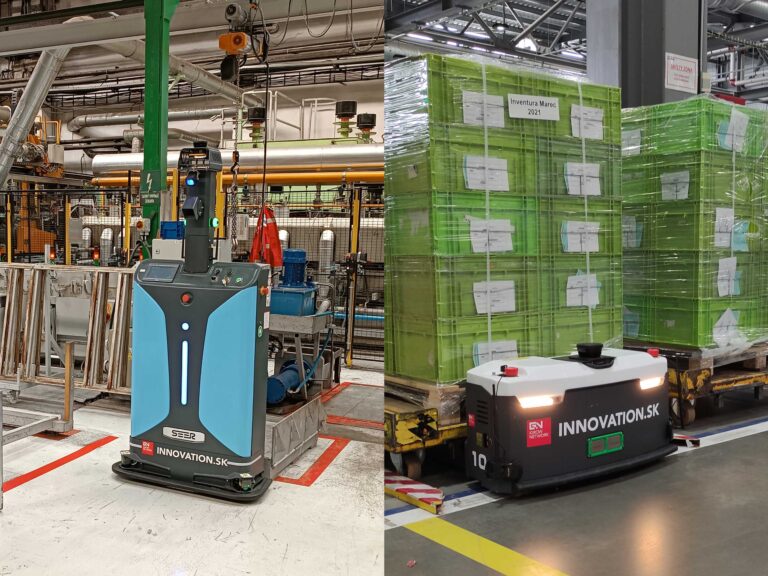

Logistics is an important part of every production or warehouse operation. It depends on, how quickly and qualitatively you can transport the material between different places. In this article, you will learn how you can increase the efficiency and reliability of your logistics system using autonomous mobile robots (AMR). However, it often happens that you have more than one possible solution – different types of AMR robots that you can use. And you need to decide on one of the possible solutions. You usually don’t have both types of AMR robots available for real physical testing. In that case, you can use computer simulation and do experiments for more strategies. The situation can be as follows:

- Variant A: Two AMR robots with a speed of 1 m/s

- Variant B: One AMR robot with speed 1,8 m/s

To answer the question of which variant is better suited to specific operating conditions, two simulation experiments were carried out. Subsequently, the parameters of the logistics system with these two variants were compared.

Simulation methodology with an emphasis on logistics system performance

First, it is necessary to build a computer simulation model. In the model, it is necessary to take into account key facts that have an impact on the achieved performance or logistics system parameters. They can be, for example:

- lengths of transport distances,

- logistics aisles, intersections, etc.,

- logistics aisles, intersections, etc.,

- possibly also the distribution of these tasks during the day – sometimes it happens that in some hours the demands on the logistics system are higher (more transports need to be carried out) and in other hours the demands are lower,

- parameters of AMR robots (speed, acceleration, deceleration, etc.),

- charging times and charging strategies of AMR robots,

- etc.

Static calculations usually take into account average numbers, but this may mean that at certain times the logistics system may not provide the necessary amount of transport tasks. After building the simulation model, the conditions of the simulation experiments are defined – in this case, the logistics system and the parameters of this system will remain the same, only the parameters and the number of AMR robots will change.

Comparison of different logistics strategies

Computer simulation provides various outputs of simulation experiments that will help you in making decisions and choosing the most advantageous logistics strategy. The results of simulation experiments can be as follows:

Results and conclusions of AMR robot simulation

The realised simulation experiment showed that two slower AMR robots were able to perform about 20% more tasks than one faster AMR robot. This means that in this case it is better to have more slower robots than fewer faster ones. Conversely, a faster AMR robot will complete the circuit faster than a slower robot. However, it is not 2x faster because it has to charge the battery more often and has a longer time to unload and load the pallet. This means that speed is not the deciding factor in this case.

Two slower AMR robots

- were able to remove all generated transport tasks (pallets) from the line

- there were a maximum of 2 pallets in the hopper (roller conveyor).

- ensured the smooth operation of the production line and warehouse

One faster AMR robot

- did not have time to take away all the generated tasks (pallets), appearing at the end of the simulation (end of day)

- in reality, possible blocking of the production line due to the filling of the roller conveyor at the end of the line

- the variant requires a larger stack capacity or a lower task generation frequency

If you need to check different logistics strategies, to determine which solution better suits your operating conditions, do not hesitate to contact us:

- by phone: +421 903 707 573

- by email: info@innovation.sk

- via the contact form: Contact – Automation Innovation

GET A 20% OFF COUPON FOR A PILOT PROJECT WITH TWO AMR ROBOTS!

We bring to your attention the opportunity to get a 20% discount coupon for a special AMR pilot project with two different AMR robots – the opportunity to realistically test different logistics strategies within one pilot project. The coupon is completely free and can be used at any time until the end of 2023.